Optimizing Evaluating Precision With Shielded Test Enclosures in Electronic Growth Procedures

In the world of digital development processes, the mission for precision and dependability in screening approaches stays vital. Protected examination rooms have arised as a crucial tool in enhancing the precision of screening procedures for electronic parts and devices. These units function as a protective barrier versus external interference, guaranteeing a controlled screening atmosphere. Nonetheless, the usage of shielded examination units prolongs beyond plain insulation, using a myriad of benefits that contribute to the total high quality and effectiveness of screening end results. By discovering the nuances of secured rooms and their effect on screening precision, a deeper understanding of their significance in digital development procedures is unveiled.

Relevance of Shielded Test Rooms

Protected rooms offer a controlled screening setting by preventing electromagnetic interference (EMI) from exterior resources that might jeopardize the integrity of electronic screening treatments. By consisting of the electromagnetic signals within the room, shielded examination rooms aid keep the consistency and repeatability of test results, ultimately enhancing the overall top quality of digital advancement processes.

Moreover, secured test rooms add to meeting regulative criteria and compliance needs in the electronics market. In significance, the importance of protected examination units lies in their capability to guard the accuracy and dependability of digital development processes with the production of a controlled and interference-free screening setting.

Kinds of Shielded Test Rooms

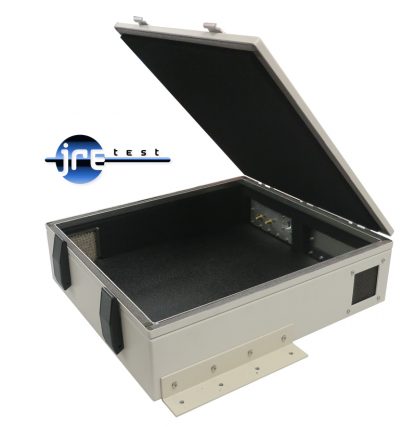

Various arrangements of protected examination units provide to diverse screening requirements and requirements in digital development procedures. Additionally, mobile shielded test enclosures provide flexibility for on-site testing or when mobility is needed. Overall, the option of secured test unit depends on the specific screening demands, the size of the gadgets being tested, and the level of flexibility needed in the digital development process.

Advantages of Making Use Of Secured Enclosures

Enhancing electro-magnetic compatibility and making certain reputable examination outcomes, protected units play a critical duty in maintaining the integrity of digital development procedures. Among the vital benefits of making use of secured units is their ability to reduce electro-magnetic interference (EMI) from exterior resources. By offering a controlled environment with minimal external interference, shielded units make it possible for exact screening of electronic tools without the threat of incorrect outcomes triggered by unwanted electromagnetic signals.

Moreover, secured units use a high level of safety and security by avoiding sensitive details from dripping out and unauthorized signals from entering the screening atmosphere. When screening proprietary or private electronic components that call for a protected screening environment., this attribute is especially important.

Additionally, secured rooms aid in abiding by regulatory requirements and certifications by supplying a controlled testing setting that meets the required electro-magnetic compatibility (EMC) standards. This guarantees that the electronic devices being checked will certainly meet the essential market standards for electromagnetic exhausts and resistance, resulting in smoother qualification processes and quicker time-to-market for products.

Considerations for Protected Unit Selection

In the process of choosing secured enclosures for electronic advancement, cautious factor to consider of ecological variables and specific needs is critical. When selecting a protected unit is the product rf chamber rochester made use of for its building and construction, the initial factor to consider. Conductive products such as steel or light weight aluminum are typically liked for their securing performance. In addition, the dimension of the room need to be appropriate to suit the digital elements being evaluated while enabling proper ventilation and cable management.

Another critical variable to think about is the level of securing needed for the testing setting. High-frequency applications may demand units with exceptional electromagnetic disturbance (EMI) shielding capacities to protect against signal interference and ensure precise test outcomes. The ease of access attributes of the room, such as panels, ports, and doors, should line up with the screening requirements to promote convenient access to the tools under test.

Finally, the transportability and scalability of the shielded room should be assessed to ensure flexibility in fitting future testing demands and possible reconfigurations. By meticulously examining these factors to consider, electronic development processes can maximize testing precision and performance with the appropriate shielded room choice.

"/>

Combination of Shielded Enclosures in Testing

The seamless combination of protected rooms into testing treatments you could try these out is important for guaranteeing precise and trustworthy digital advancement processes. Protected enclosures play an essential role in reducing external disturbance throughout screening, thus enhancing the accuracy of outcomes. When incorporating protected rooms into screening settings, it is very important to think about aspects such as the size of the enclosure, the sort of protecting material used, and the details screening requirements of the electronic parts being examined.

One key aspect of incorporating protected enclosures right into screening is ensuring proper connection within the enclosure. This includes developing safe and secure connections for power sources, information transfer, and tracking equipment to properly carry out examinations while preserving the shielding performance of the room. In addition, carrying out proper air flow and cooling systems within the unit is important to avoid getting too hot of electronic elements during testing treatments.

Final Thought

Finally, the usage of shielded test units in electronic advancement processes is important for making the most of screening accuracy. Different kinds of shielded rooms supply different benefits, and mindful consideration must be offered to choosing one of the most appropriate one for details screening needs. Integrating secured enclosures into the screening procedure can significantly enhance the integrity and performance of electronic testing treatments.

Secured units provide a controlled screening setting by preventing electromagnetic interference (EMI) from external resources that might compromise the stability of digital testing treatments - rf chamber rochester. By including the electromagnetic signals within the room, secured examination units aid maintain the consistency and repeatability of examination outcomes, ultimately enhancing the general top quality of digital growth procedures

When incorporating secured enclosures right into screening settings, it is vital to consider factors such as the size of the unit, the kind of securing product utilized, and the certain testing demands of the electronic components being evaluated.

One key facet of incorporating protected rooms into testing is ensuring proper connection within the unit. Incorporating protected rooms into the screening procedure can substantially enhance the reliability and effectiveness of digital testing procedures.